Engineering

Multilayer metrology: Combining optical spectral measurements and machine learning

Multilayer metrology: Combining optical spectral measurements and machine learning

A joint research team of Prof. Jungwon Kim and Samsung Electronics demonstrate a non-destructive method for thickness characterization of 3D semiconductor devices. The team could characterize the thickness of each layer with an average error of 1.6 Å over >200 layers.

Article | Fall 2021

With the recent explosive demand for data storage, ranging from data centers to various smart and connected devices, the need for higher-capacity and more compact memory devices is constantly increasing. As a result, semiconductor devices are now moving from 2D to 3D. The 3D-NAND flash memory is the most commercially successful 3D semiconductor device today, and its demand for supporting our data-driven world is now growing exponentially.

The scaling law for 3D devices is achieved by stacking an increasing number of semiconductor layers, well above 100 layers, in a more reliable way. As each layer’s thickness corresponds to the effective channel length, accurate characterization and control of layer-by-layer thickness is critical. Unfortunately, to date, in structures with hundreds of layers, accurate non-destructive measurement of each layer’s thickness has not been possible, which creates a serious bottleneck in the future scaling of 3D devices.

In a new paper published in Light: Advanced Manufacturing, a team of engineers from KAIST and Samsung Electronics Co. Ltd., led by Professor Jungwon Kim of KAIST has developed a non-destructive thickness characterization method by combining optical spectral measurements and machine learning. By exploiting the structural similarity between semiconductor multilayer stacks and dielectric multilayer mirrors, spectroscopic optical measurements, including ellipsometric and reflectance measurements, are employed. Machine learning is then used to extract the correlation between spectroscopic measurement data and multilayer thickness. For multilayer stacks with more than 200 layers of oxide and nitride, the thickness of each layer over the entire stack could be determined with an average of approximately 1.6 Å root-mean-square error.

In addition to the accurate determination of the multilayer thickness under normal fabrication conditions, which is helpful for controlling etching and deposition processes, the research team developed another machine learning model that can detect outliers when layer thicknesses significantly vary from the design target. It used a large number of simulated spectral data for more effective and economical training and could successfully detect the faulty devices and the exact erroneous layer location in the devices.

“The machine learning approach is useful for eliminating measurement-related issues,” said Hyunsoo Kwak, a doctoral student at KAIST and first author of the study. “By using noise-injected spectral data as input to the machine learning algorithm, we can eliminate various errors from measurement instruments and changes in material properties under different fabrication conditions,” he added.

“This method can be readily applied for the total inspection of various 3D semiconductor devices,” said Professor Kim, “which is exemplified by the fact that all the data used in this work were obtained in commercial 3D NAND manufacturing lines of Samsung Electronics.”

This research was supported by the Industry–Academia Cooperation Program of Samsung Electronics Co., Ltd.

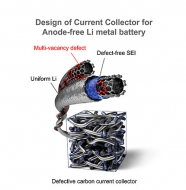

Fig 2. Principles of the proposed multilayer thickness metrology method.a. Multilayer structure with alternating silicon oxide (blue) and silicon nitride (white) layers on a Si substrate. In the layer deposition process, undesirable thickness variations can occur.b. Schematics of a typical spectroscopic ellipsometer (left) and reflectometer (right).c. Examples of ellipsometric (left) and reflectance (right) measurement data. For the ellipsometric measurement data, the solid and dashed lines denote cosine-delta and tangent-psi, respectively. The grey areas indicate the unused spectral range, where the measurement errors between the instruments are large.

Read more