KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Fall 2025 Vol. 25Biodegradable 3D Printing Filament with Outstanding Printability

Biodegradable 3D Printing Filament with Outstanding Printability

For a sustainable environment, expanding the application spectrum of biodegradable plastics is crucial. 3D-printed prototypes fabricated from biodegradable/non-biodegradable thermoplastics and their blends were biologically degraded by microorganisms in the natural environment.

Article | Fall 2022

Three-dimensional (3D) printing technology, also known as additive manufacturing, has revolutionized conventional designing and prototyping practices by enabling individuals to create artifacts quickly and affordably. Thermoplastic blends are applied to 3D printing to improve functionality. While the thermal, chemical, and mechanical properties of 3D-printed blends are typically examined, biodegradability has rarely been the subject of research, despite the presence of biodegradable parts (e.g., polylactic acid, PLA) in the plastic blends.

The worldwide 3D printing market has expanded at a breakneck pace. As a result of this, massive amounts of non-biodegradable plastic waste resulting from spent thermoplastic resins have been generated. Biodegradable polymers are gaining in popularity as a viable option for mitigating the accumulation of plastic in the natural environment. In line with this, biodegradability is an important property for generic products such as food packaging, fishing gear, and customized prototypes, all of which can be made via additive manufacturing.

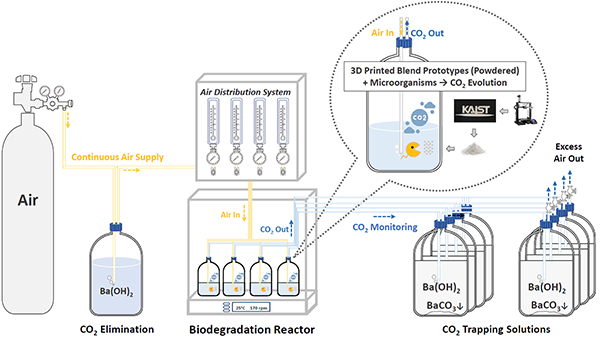

Prof. Jaewook Myung’s group, also referred to as the WITHLAB (Waste-Innovating Technologies for a Humanity Laboratory), in the Department of Civil and Environmental Engineering at KAIST is dedicated to illuminating the true biodegradability of biodegradable plastics and to broadening the range of bioplastic applications. WITHLAB has evaluated the 3D-printing performance and biodegradation behavior of various plastics and their blends, including biodegradable polylactic acid (PLA), poly(3-hydroxybutyrate) (PHB), and non-biodegradable high-density polyethylene (HDPE), polypropylene (PP).

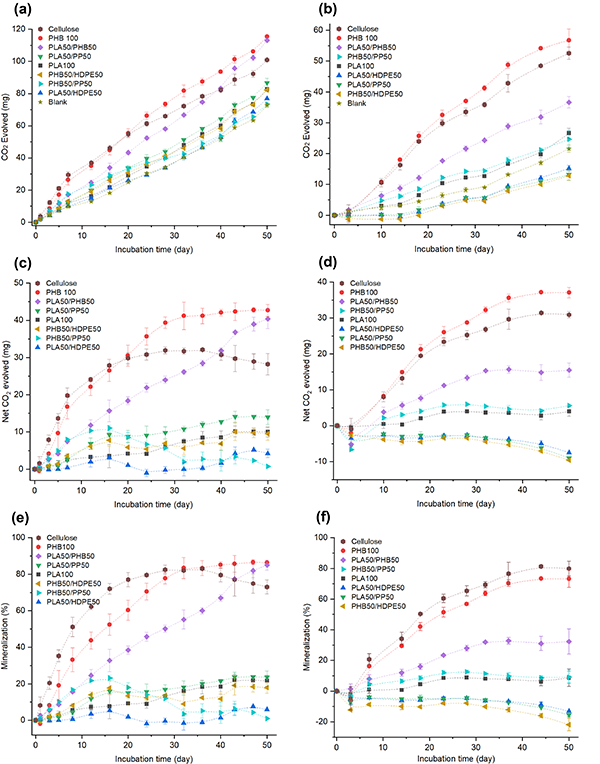

WITHLAB revealed that biodegradable plastics (PLA, PHB) and a blend of these types (PLA/PHB) exhibited significant biodegradation. The carbons in these polymers are biologically mineralized into gaseous end products such as carbon dioxide. The biodegradation level of the PLA/PHB (50:50 wt%) blend met the ASTM D6400-12 standard’s requirements for compostable labeling (greater than 90% threshold with respect to cellulose in 180 days). Biodegradable/non-biodegradable blends (PLA/HDPE, PLA/PP, PHB/HDPE, PHB/PP) barely biodegraded. The immiscible biodegradable/non-biodegradable plastic blends displayed signs of partial breakdown and even antagonism to biodegradation due to phase separation and the barrier effect.

Utilizing polyolefins such as HDPE and PP via 3D printing can be a promising option due to their versatile properties and dominance in the commodity plastic market. However, the 3D printing of HDPE and PP has been problematic due to poor adhesion, warping deformation, and crystallization-induced volume contraction. WITHLAB demonstrated that HDPE and PP could be successfully 3D printed without the addition of additives or compatibilizers by creating blends with PLA and tweaking the printing parameters. They also discovered that a biodegradable PLA/PHB blend has excellent printing performance.

Although PLA/HDPE and PLA/PP blends are resistant to biodegradation, low-cost polyolefins (HDPE, PP) as well as some notable improvements in the mechanical properties (increased elongation) make them promising FDM 3D-printing resources. On the other hand, the outstanding printing performance, improved Young’s modulus, and synergetic biodegradation behavior of the PLA/PHB blend suggest that it is an excellent choice as a sustainable FDM printing resource.

Publication:

S. Choe, Y. Kim, G. Park, D.H. Lee, J. Park, A.T. Mossisa, S. Lee, J. Myung (2022), Biodegradation of 3D-printed biodegradable/non-biodegradable plastic blends, ACS Appl. Polym. Mater., in press. DOI: https://doi.org/10.1021/acsapm.2c00600 (This article was selected as a supplementary journal cover article.)

Most Popular

Wearable Haptics of Orthotropic Actuation for 3D Spatial Perception in Low-visibility Environment

Read more

Soft Airless Wheel for A Lunar Exploration Rover Inspired by Origami and Da Vinci Bridge Principles

Read more

TwinSpin: A Novel VR Controller Enabling In-Hand Rotation

Read more

How AI Thinks: Understanding Visual Concept Formations in Deep Learning Models

Read more

Title WSF1 Vision Concept: Redefining Wearable Robotics through Human-centred Mobility Design

Read more