KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Fall 2025 Vol. 25A new structural surface design for anodes in the next generation lithium batteries

A copper current collector with increased structural dimensions and hierarchy is developed for high-performance lithium-metal battery anodes. The new surface enables inward nucleation of lithium, thus enhancing the cycle life of lithium-metal battery by 364%

A research team led by Prof. Sanha Kim in ME department has succeeded in developing an anode current collector for high-performance lithium-metal batteries using micro/nano hierarchical surface structures. As the energy demand continues to increase, the development of batteries with higher energy density and better performance is becoming more important.

Lithium-ion batteries, which are mainly used as commercial batteries, use graphite as an active anode material, which theoretically has a clear limit in energy density. Accordingly, lithium-metal batteries with high energy density that replace the anode material of existing lithium-ion batteries with lithium-metal have been attracting attention. However, in order to commercialize lithium-metal batteries, the problem of maintaining stability and performance must first be resolved. The main cause of this problem is the formation of dendrite in the form of tree branches. These are formed on the lithium-metal anode surface by heterogeneous electrodeposition of Li due to its inherent instability in organic electrolytes. The team began research on a copper current collector (Cu CC) based on a micro/nano hierarchical structure to suppress the formation of dendrites and improve the stability and performance of lithium-metal batteries.

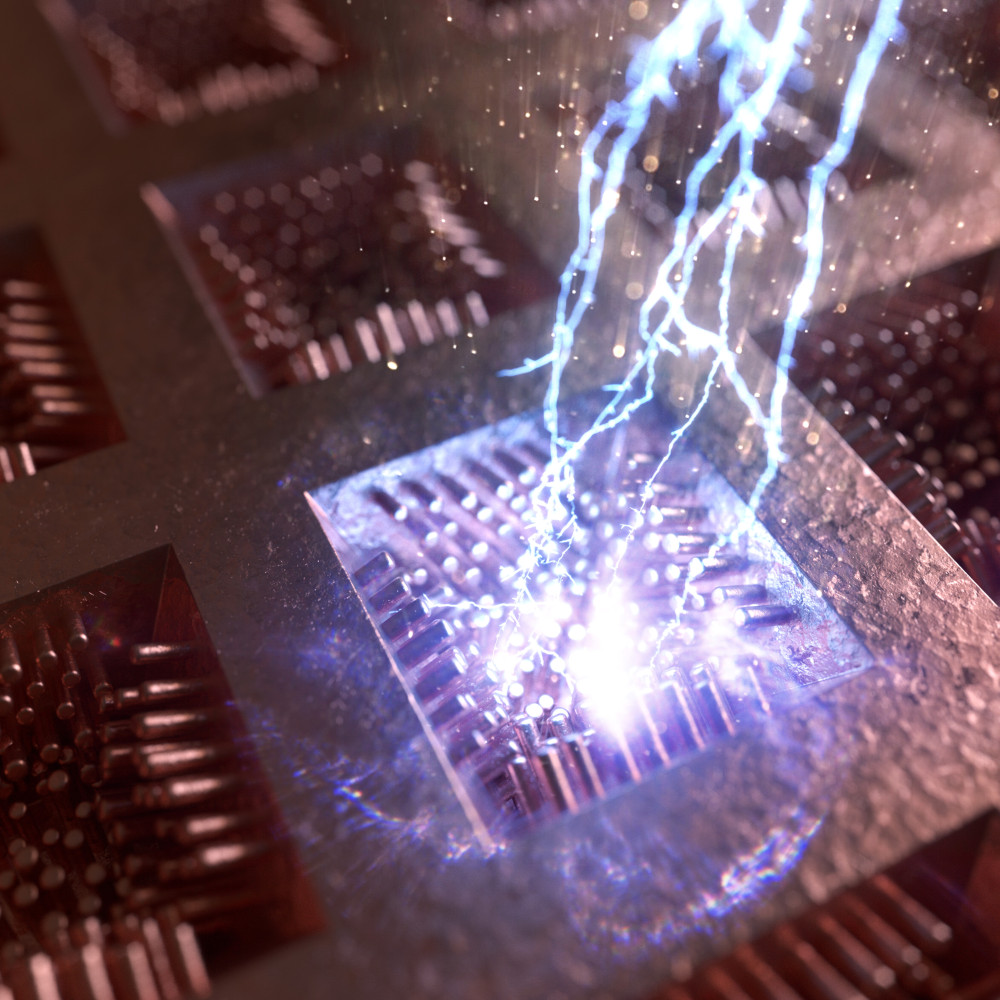

![Figure 1. Illustration for dendrite failure in Li-metal batteries and research objectives: Structural optimization in microscale, selective nucleation of Li via micro- and nanostructured hierarchical surface, and development of facile/largescale fabrication process of three-dimensional and hierarchically structured current collector with selective nucleation and inward growth characteristics. [Copyright: Advanced Energy Materials 2023, 13, 2202321.]](/_files/custom_board_contents2/20230823//427611751c56110b0617ed666ead51d4.png)

![Figure 2. Concentration of electrical field inside microcavities via nanorods resulting in Li nucleation at nanorod tips. [Copyright: Advanced Energy Materials 2023, 13, 2202321.]](/_files/custom_board_contents2/20230823//af92c6e18e1a58e39ac456cd2782608d.png)

![Figure 3. Facile, large-scale fabrication of hierarchically structured current collectors with selective inward growth characteristics and its performance as a lithium metal battery anode. [Copyright: Advanced Energy Materials 2023, 13, 2202321.]](/_files/custom_board_contents2/20230823//df8734fbd56c2434224c16e35eba3a55.png)

Most Popular

TwinSpin: A Novel VR Controller Enabling In-Hand Rotation

Read more

Wearable Haptics of Orthotropic Actuation for 3D Spatial Perception in Low-visibility Environment

Read more

Lighting the Lunar Night: KAIST Develops First Electrostatic Power Generator for the Moon

Read more

A Next-Generation Microbial Platform for Eye-Health Lutein Production

Read more

Movie 1. A soft airless wheel constructed from metallic strips demonstrates both high deformation capability and mechanical stability using rigid materials.

Read more