KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24100% real fabric functional circuit with a missing 4th electronic component of memristor beyond resistor, capacitor and inductor

100% real fabric functional circuit with a missing 4th electronic component of memristor beyond resistor, capacitor and inductor

A functional circuit with a memristor, which was fabricated on an interwoven fabric, was demonstrated. The memristor is a missing fourth electronic component beyond well-known resistor, capacitor, and inductor. This research paves the way for wearable and smart fibertronics, finally constructing a fabric computer

Article | Spring 2018

Fibertronics is an emerging technology in which electronic components are embedded on textile fibers. Sometimes called advanced electronic-textile (e-textiles), fibertronics has been explored as an ideal platform for developing wearable electronics. Conventional fabric-based electronics suffer from various technical problems that need to be solved, including their requirements for low power consumption, high integration density, water-stable material for outdoor use, and complicated fabrication processes, such as masking, etching, and evaporation steps. For these reasons, fibertronics has recently attracted a great deal of attention as true e-textile nanotechnology.

Hagyoul Bae, Byung Chul Jang, Prof. Sung Gap Im, Prof. Sung-Yool Choi, and distinguished Prof. Yang-Kyu Choi, have developed “A novel memristor-based functional device and circuit on cotton fabric for fibertronics” to provide a roadmap for an energy-efficient circuit platform of fabric for future technology.

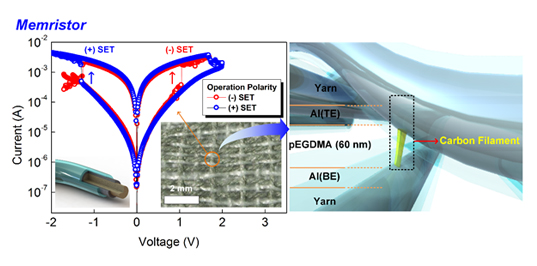

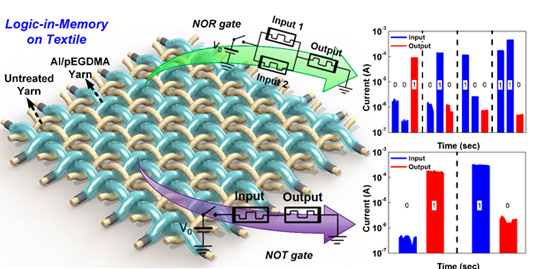

The collaboration team of Prof. Yang-Kyu Choi and Prof. Sung-Yool Choi demonstrated a memristive nonvolatile logic-in-memory circuit using the pEGDMA-Textile Memristor (ETM) on real cotton yarn as a step toward implementing a genuine 100% fabric computer. The ETM is composed of two aluminum (Al)/pEGDMA-coated cotton yarns in a woven form to form a large-scale memristor crossbar array using conventional weaving tools. Each strand of Al/pEGDMA-coated yarn is cross-linked to every other line by intercalating with unprocessed yarns to isolate each ETM within a crossbar array. The ETM was fabricated via the initiated chemical vapor deposition (iCVD) process with a significant contribution from Prof. Sung Gap Im’s group, enabling the solvent-free deposition of polymer thin film, which appears very attractive compared to other polymer-based memristors due to its good water resistance and versatile wearability on any substrate.

The research team also demonstrated that the basic Boolean functions, including NOT, NOR, OR, AND, and NAND logic gates, were reliably implemented for data processing and storage within the ETM based crossbar array. Furthermore, they experimentally demonstrated a ‘half adder’, which is a kind of logic functional block. It was just comprised of only 5 ETMs. The results of the study show the feasibility of the ETM circuit for energy-efficient wearable fibertronics.

The research team also demonstrated that the basic Boolean functions, including NOT, NOR, OR, AND, and NAND logic gates, were reliably implemented for data processing and storage within the ETM based crossbar array. Furthermore, they experimentally demonstrated a ‘half adder’, which is a kind of logic functional block. It was just comprised of only 5 ETMs. The results of the study show the feasibility of the ETM circuit for energy-efficient wearable fibertronics.

Robustness to environmental stresses should be confirmed for body-friendly fibertronics used in outdoor environments. In this sense, washability is crucial for repeated practical use. The research team carried out a washing experiment using a household washing machine with a 0.1% concentration of detergent (water/detergent = 1000:1). Transmission electron microscopy (TEM) and energy dispersive spectrometer (EDS) analyses were performed before and after the washing process with chemical and mechanical stresses. The results indicated that the pEGDMA suffered negligible degradation due to chemical or mechanical damages and the ETM devices were robust enough to usual washing conditions. Furthermore, the ETM devices showed outstanding water resistant stability after being held in a harsh environment with relative humidity in the range of 20% to 90% for 1 hour. Note that the ETM devices were laundered in the washing machine without extra encapsulation coating. The unique washing-resistant characteristic of the ETM devices is attributed to not only the outstanding chemical stability of the pEGDMA material to water but also the excellent mechanical and long-term stability of the Al-coated yarn against oxygen and moisture. On the basis of the environmental test results, it is concluded that the ETM is suitable for practical wearable fibertronics applications.

This research was published in Nano Letters (DOI:10.1021/acs.nanolett.7b03435) on September 11, 2017.

http://pubs.acs.org/doi/abs/10.1021/acs.nanolett.7b03435

https://humantech.samsung.com/saitext/index.jsp

Most Popular

When and why do graph neural networks become powerful?

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more