KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Mobile Clinic Module: Inflatable Isolation Ward for Infectious Disease Patients

Mobile Clinic Module: Inflatable Isolation Ward for Infectious Disease Patients

A Mobile Clinic Module (MCM) is a negative pressure isolation ward that can be effectively transported, built, and stored in a short period of time. Through a combination of air tents, frames, and functional panels, it is possible to rapidly build various medical facilities in an infectious disease outbreak.

Article | Spring 2021

In a pandemic situation, such as COVID-19, the demand surges for negative pressure wards to treat patients with moderate to severe infections. Existing prefabricated construction methods have been focused only on quarantine, which makes resulting structures inappropriate for use as a medical facility and challenging to store the ward during non-crisis periods. To perform medical activities effectively, a user-centered design is required considering the needs of various stakeholders such as medical staff, patients, and administrators.

The research team led by Prof. Tek-Jin Nam from the Department of Industrial Design developed Mobile Clinic Module (MCM), a modular negative pressure ward system that enables building, effectively transporting, and storing medical environments during non-crisis periods for moderate to severe patients in a short time. MCM considers not only the basic requirements of the utility aspects of negative pressure provisions, such as functionality (bio-safety), economic viability, and efficiency (construction and storage), but also originality, usability, and emotional satisfaction for the stakeholders such as patients and medical staff.

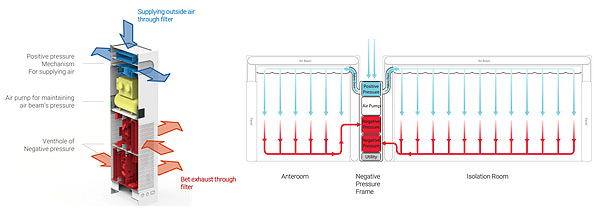

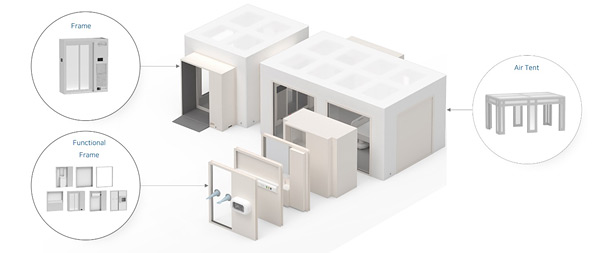

MCM comprises three components: the frame, the air tent, and the function panel. It is possible to build various negative pressure medical facilities through their combination. The frame allow people to pass through between tents. The negative pressure frame is a multifunctional air-controlling device that includes positive and negative pressure devices, which can effectively set differential pressure in both directions of the room. The air tent is composed of the air beam or double layered structure. The inflatable structure make it easy and quick to build a sufficient room for isolated patients. Ventilation outlets that can produce an air shower effect on the ceiling were applied based on computational fluid dynamics. The functional panel reinforces the structural stability of the tent while providing the function that satisfies its purpose. The medical panel supplies essential medical resources such as oxygen and compressed air for severe patients. The glove & pass box panel can be used to transfer the necessary articles or support light diagnosis and treatment without wearing protective clothing.

The basic MCM unit consists of the anteroom and the patient room, which can be installed within 15 minutes. Compared with the reconstruction method, MCM is expected to save about 80% in cost. Compared with the prefabricated architecture, volume is expected to decrease by 75%, and weight by 60%. Within four months, user-research, design, prototype development, and a clinically-operable ward were completed. The medical staff and patients’ usability and satisfaction, as well as stability of the constructed ward, were evaluated in the Korea Institute of Radiological and Medical Sciences’ outdoor parking lot space with 500 square meters where the ward was installed.

Most Popular

When and why do graph neural networks become powerful?

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more