KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2026 Vol. 26A highly efficient PET alternative plastic monomer producing microbial strains were developed. These strains were based on various production strategies for five types of eco-friendly pseudo-aromatic polyester monomers that can replace existing fossil fuel-based plastics.

Currently, there has been an increase in global environmental problems caused by plastic waste. As a potential solution, biodegradable plastics, especially those capable of replacing widely used polyethylene terephthalate (PET) in plastic bottles, have garnered significant attention. Pseudo-aromatic dicarboxylic acids are emerging as eco-friendly polymer monomers due to their superior material properties and high biodegradability compared to PET when polymerized. However, chemical methods for producing pseudo-aromatic dicarboxylic acids face challenges such as low yield and selectivity, complex reaction conditions, and the generation of hazardous waste. These obstacles have hindered research progress into alternative plastics based on these compounds.

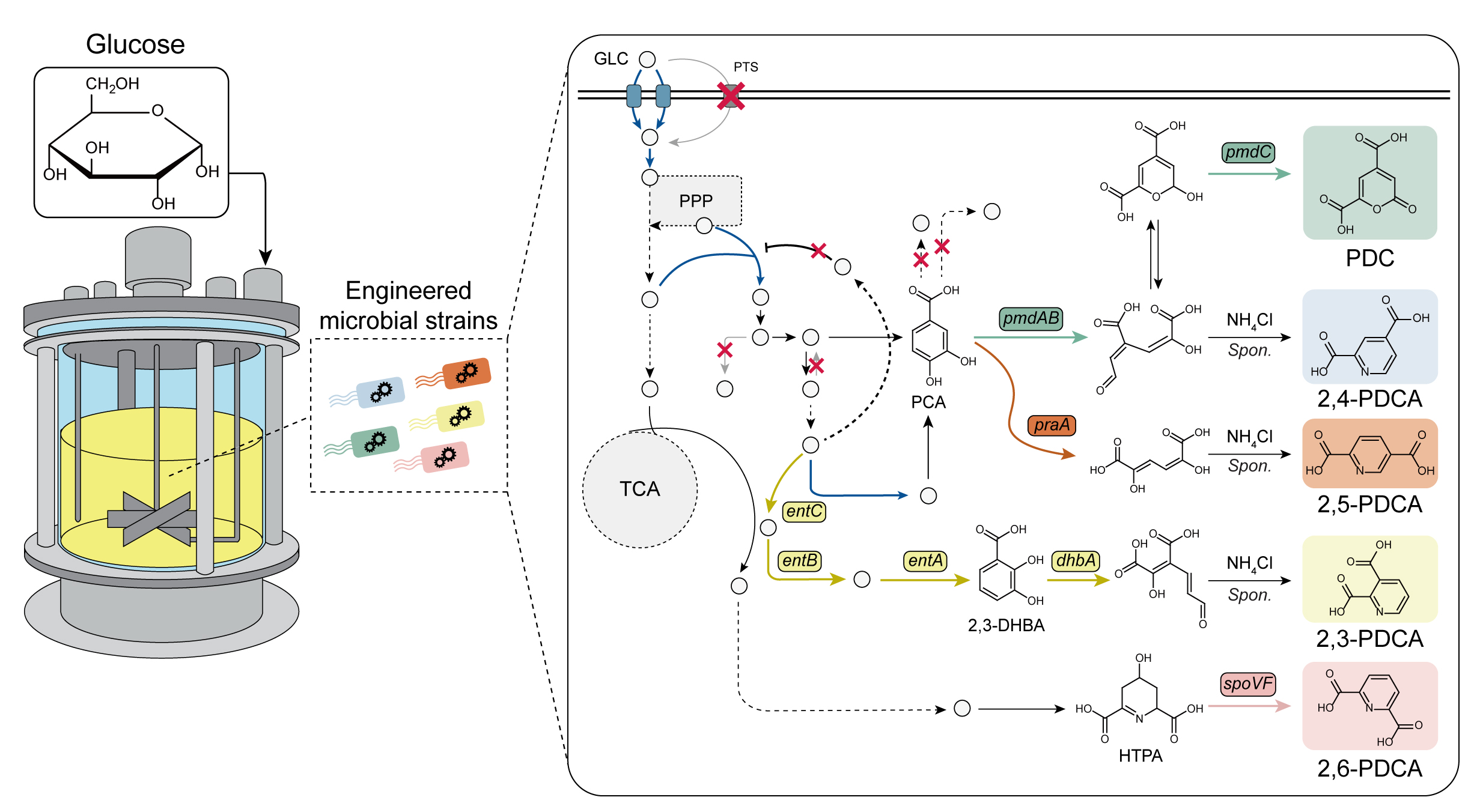

To address this issue, systems metabolic engineering strategies were employed to develop microbial strains of Corynebacterium glutamicum, a bacterium primarily used for amino acid production, capable of efficiently producing five pseudo-aromatic dicarboxylic acids: 2-pyrone-4,6-dicarboxylic acid (PDC) and four types of pyridine dicarboxylic acids (PDCAs; 2,3-, 2,4-, 2,5-, and 2,6-pyridine dicarboxylic acids).

The metabolic engineering techniques were utilized to build a platform microbial strain that enhances the metabolic flow of protocatechuic acid, which is used as a precursor for several pseudoaromatic dicarboxylic acids, and prevents the loss of precursors. Based on this, the genetic manipulation target was discovered through transcriptome analysis, producing 76.17 g/L of 2-pyrone-4,6-dicarboxylic acid. Moreover, three types of pyridine dicarboxylic acid production metabolic pathways were constructed, where the 2,3-PDCA biosynthesis pathway was newly discovered. The constructed strains successfully produced 2.79 g/L of 2,3-pyridine dicarboxylic acid, 0.49 g/L of 2,4-pyridine dicarboxylic acid, and 1.42 g/L of 2,5-pyridine dicarboxylic acid.

In addition, 15.01 g/L of 2,6-pyridine dicarboxylic acid production was confirmed through the construction and reinforcement of the 2,6-pyridine dicarboxylic acid biosynthesis pathway, successfully producing a total of five similar aromatic dicarboxylic acids with high efficiency. As a result, the world's highest concentrations of 2,4-, 2,5-, and 2,6-pyridine dicarboxylic acids production was achieved. In particular, 2,4-, 2,5-pyridine dicarboxylic acid achieved production on the scale of g/L, which was previously produced in extremely small amounts (mg/L).

This research highlights the precise regulation of microbial metabolic pathways to expand the production spectrum and efficiency of polymer precursors and alternative plastics that are challenging to produce via chemical methods. Furthermore, it is expected to enhance the competitiveness of the bio-based monomer industry, contributing to the eventual replacement of the petroleum-based chemical industry. These findings were published in the October 30 issue of the Proceedings of the National Academy of Sciences (PNAS).

Most Popular

Soft Airless Wheel for A Lunar Exploration Rover Inspired by Origami and Da Vinci Bridge Principles

Read more

Dual-Action Hydrogel Offers New Hope for Rheumatoid Arthritis Treatment

Read more

Wearable Haptics of Orthotropic Actuation for 3D Spatial Perception in Low-visibility Environment

Read more

Lighting the Lunar Night: KAIST Develops First Electrostatic Power Generator for the Moon

Read more

GPU-NPU-PIM Integration Technology for Generative AI Clouds

Read more